Flokk’s partnership with Hydro adds new dimension of sustainability to HÅG Celi

Flokk’s design collaboration with aluminium experts Hydro combines cutting edge recycling technology with innovative furniture design, resulting in a chair with the lowest carbon footprint possible

- Design

- Sustainability

- HÅG

For many years, Flokk has been on a mission to create more environmentally conscious seating. Using recycled materials is a vital part of this effort, as it helps preserve natural resources while reducing waste, energy consumption, and carbon emissions.

When we designed the HÅG Celi, we identified aluminum as a key material for many components early in the process. To minimize our environmental impact, Flokk collaborated with experts in the aluminum industry to revolutionize our use of this highly recyclable material. Through our partnership with Hydro, we successfully developed components for the latest HÅG design that strike a perfect balance between high strength, low weight, and a minimal carbon footprint.

Watch below - Flokk & Hydro on making the HÅG Celi

Aluminium – the perfect recycleable material

Hydro stands as one of the world's largest aluminium producers and manufacturers of extruded aluminium components and solutions. Founded in Norway, they now operate in over 40 countries, actively advancing the use of high-quality recycled aluminium to significantly reduce their carbon footprint. Aluminium, being endlessly recyclable without losing its properties, serves as a prime example of a circular economy material.

In manufacturing, various aluminium alloys are commonly employed, boasting hundreds of slight variations tailored to enhance specific characteristics. Historically, sorting post-consumer scrap aluminium—material already used in other applications and subsequently discarded, such as window frames—proved challenging on a large scale due to economic constraints. Consequently, all these scrap materials were typically recycled together, with primary aluminium introduced to maintain a consistent composition.

Cutting edge sorting technology

To tackle this recycling challenge head-on, Hydro invested in precise scrap aluminium sorting methods. Their state-of-the-art sorting facilities are outfitted with cutting-edge technology. Each facility specialises in handling different types of scrap, ranging from drink cans to window frames salvaged from building demolitions.

The scrap materials progress through a series of shears, shredders, and magnets to remove non-metal components, resulting in a consistent material flow. In the most advanced facility, this flow passes through an x-ray machine, which accurately detects and ejects unwanted alloys using an array of synchronized air jets. The chips then undergo a de-lacquering process before being melted and recast. Each facility yields an impressive 100 tonnes of sorted aluminium chips daily, enabling Hydro to provide high-quality recycled aluminium on an industrial scale.

This unique process allows Hydro to produce CIRCAL, one of the world's most sustainable aluminium alloys, with a minimum post-consumer recycled content of 75%, resulting in an exceptionally low carbon footprint.

Watch below - How Circal is made

The perfect mix – Hydro Pro3 & Flokk Collaboration

The next stage on the journey from scrap to new product is where Flokk and the HÅG Celi come in. Early on, the design team behind the HÅG Celi identified aluminium as the best material to use for the legs and frame, and Hydro as the perfect provider. Working together, Flokk and Hydro identified the key characteristics the aluminium components would require, and began to explore the various aluminium alloys they could use. This process relies on the decades of research and experience conducted by Hydro, which has been compiled into their signature modelling program called Pro3.

Speaking about the collaboration, Morten Kildahl, Senior Project Manager at Flokk says, "We initially evaluated several concepts for the frame of the chair, looking for solutions and materials that would minimize our environmental impact, while at the same time answering our demands for visual design, durability, and industrialization. It became clear that a welded construction from extruded aluminium would tick all the boxes. Welding aluminum was however a new production process for us at Flokk, so the cooperation with Hydro was crucial in optimizing the design of the extruded profiles for this process”

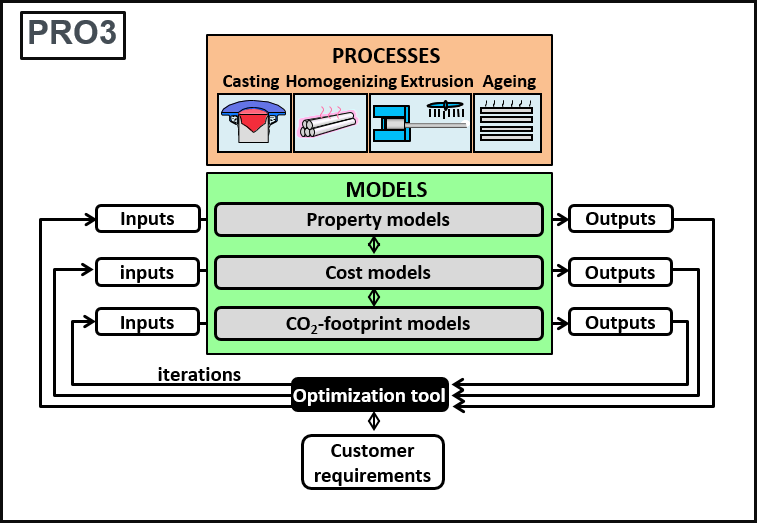

Figure I - An overview of Hydro's PRO3 Modeling software methodology

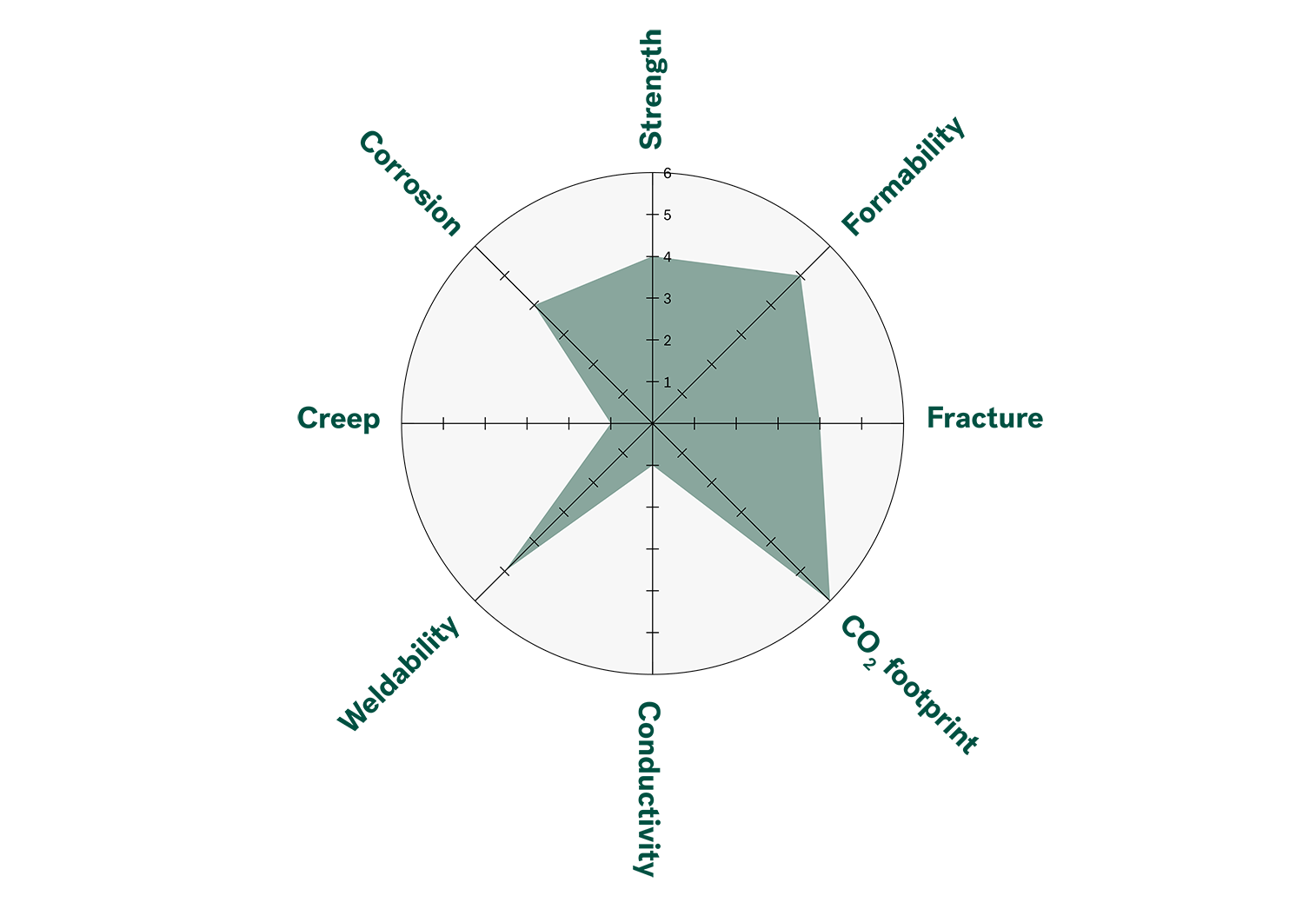

Figure II - an overview of the key characteristics defined by Flokk in collaboration with Hydro when designing the aluminium components of the HÅG Celi

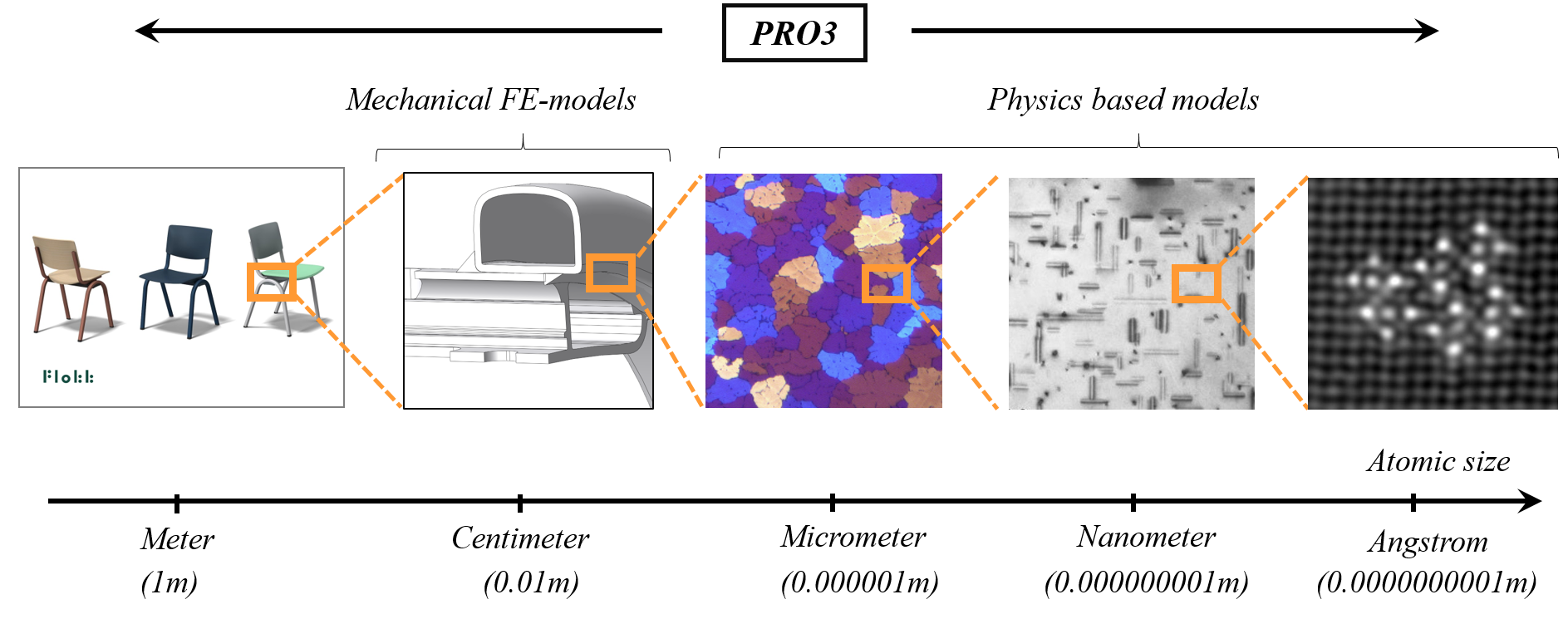

Figure III - Example of the level of detail available with the PRO3 modelling software

PRO3 is an innovative methodology that has been developed for optimization of product properties, production costs, and environmental impact (e.g CO2 footprint) in fabrication of aluminium alloys (see Figure I). The PRO3 software utilises mechanical models in combination with physics-based, ranging from meter to atomic level (see Figure III), which can predict the impact of adding various alloying elements into the mixture.

The process begins with the Flokk design team providing models of the aluminium components and the minimum requirements of various properties, including weight, strength, and carbon footprint to name a few (see Figure II). The program will then run simulations of hundreds of alloys available, providing all the data to select the best material that meets the requirements. It is a delicate balancing act, with an increase in one property likely to affect another, to find the right compromise, including potential reshaping of the parts.

Once the optimum recipe has been identified, the components are ready to be produced. Hydro uses extrusion, where a cast log of aluminium (known as a billet) is heated to approximately 500 degrees, before being passed through a steel die which creates the required shape of the component. The component is then quenched in air or water, stretched in order to release any residual tension and artificially aged to meet strength requirements. Once the aluminium components are ready, they are cut to length and then shaped and welded to the customer’s specification before shipping for assembly.

HÅG Celi – A uniquely sustainable conference chair

Each HÅG Celi contains 2.5kg of Hydro CIRCAL aluminium that has passed through this entire process, from the scrap heap to a new life, imbued with characteristics to ensure it remains in use for many years to come.

‘’Our environmental philosophy contains a number of no-compromise elements. Maximizing the use of post-consumer recycled material is one of them." Says Christian Lodgaard, Senior Vice President of Product & Brands at Flokk, continuing, "With Hydro we found a perfect match in this thinking, and the technological savviness & determination to bring new sustainable solutions to life at scale’’

With additional time and resources, the model devised for the HÅG Celi can be improved, using less metal, with thinner walls whilst still providing the same desired properties. CIRCAL too, is also just a stepping stone to new developments, with HYDRO currently working on a 90% post-consumer content aluminium.

“Our ambition is to deliver the first commercial volumes of near-zero carbon aluminium already in 2022, based on 100% recycled post-consumer scrap,” says Hilde Merete Aasheim, Hydro’s President & CEO.

This might also interest you

A deeper look at the history behind the HÅG x Recouture Collab

Learn how åkle developed across Norway, why the motifs look the way they...

HÅG x Recouture : Heritage craft for a design icon

Learn how Recouture give traditional Norwegian åkle new life, in...

HÅG SoFi – now available in tumbled aluminium

Extending the beauty of tumbled aluminium to HÅG SoFi — versatile,...