infinitely recyclable

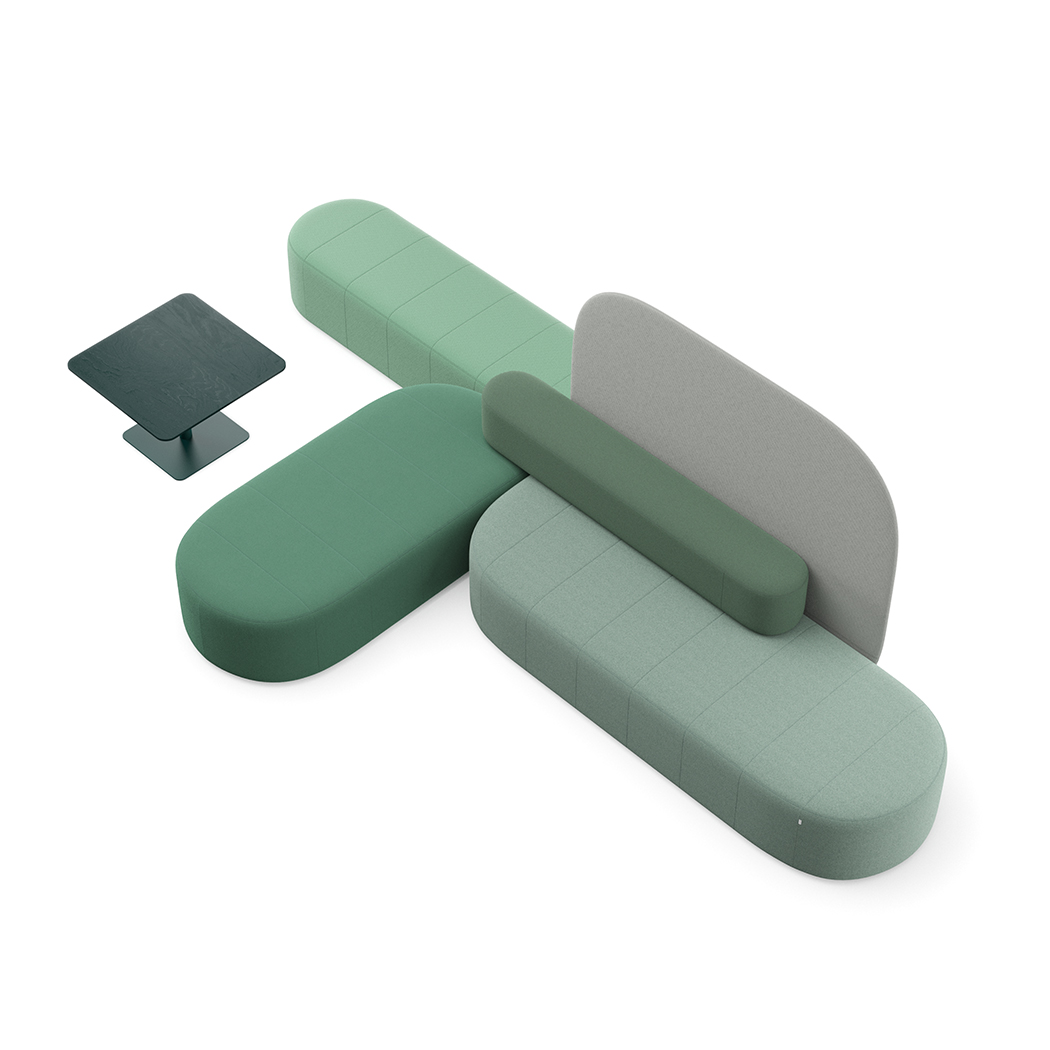

Recognising that the climate crisis urgently demands a radical rethinking of the way in which upholstered contract furniture is made, and keen to address the rapid global working culture, Flokk asked Pearson Lloyd to develop a furniture family that responded to both. The result, Revo, is nothing short of a revolution.

Revo’s success as a modular furniture system is largely down to the fact it is extremely lightweight. This is thanks to Profim and Pearson Lloyd’s decision to use recycled expanded polypropylene (REPP) rather than the plywood commonly used to make upholstery frames, thus reducing the product weight by around 40%.

“Revo represents a radical rethinking of the way upholstered contract furniture is made in response to the climate crisis. Replacing the plywood base structure with REPP (recycled expanded polypropylene) maximises the potential reuse of the base materials. Plywood has no circularity. REPP, which is already in its second life, can be fully remoulded for a third, a fourth, ad infinitum.” – Luke Pearson, Pearson Lloyd

First used by Pearson Lloyd to create the Link room divider system in 2007, REPP is a highly versatile closed-cell bead foam with a host of beneficial properties, including outstanding energy absorption, an exceptionally high strength-to-weight ratio, and resistance to impact, water and chemicals. Most importantly, it is 100% recyclable and remouldable. With no additives (such as glass fibre), REPP can be endlessly remoulded, meaning that at the end of its life, all Revo components can be separated into their component materials, and returned to the manufacturing cycle.

_resize.jpg)