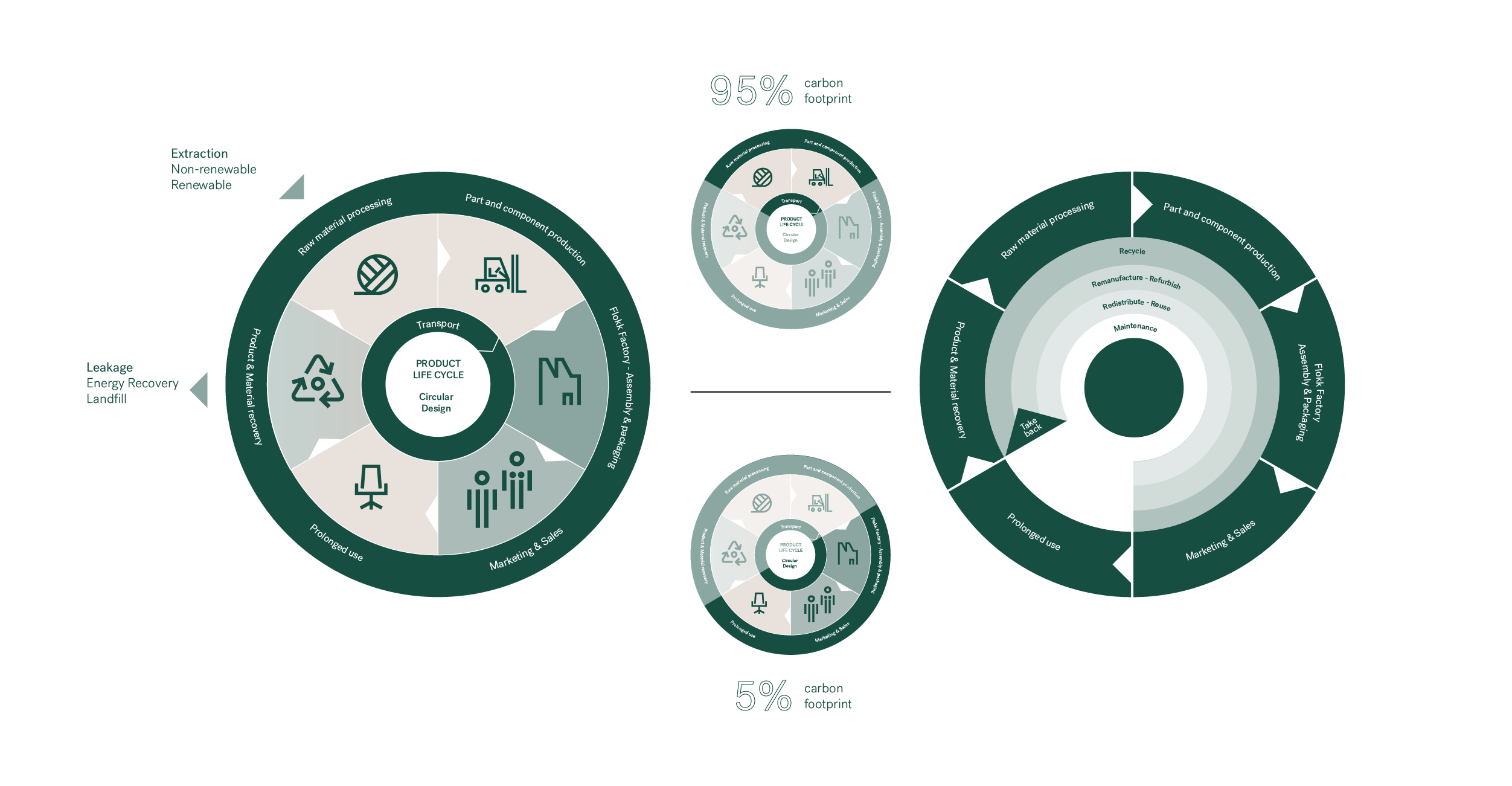

Flokk’s approach to circular design

In the 1990s, Flokk did just that – developing a range of development principles to enable circular design. Named 5-III (five three), it features five circular design principles to take care of three focus areas – climate, resources and health.

The five circular design principles are:

Low weight:

By making a product through weight optimization and smart dimensioning of parts, you are using fewer resources. This reduces the strain on the environment, especially when production is in the thousands of units. Lightweight also means lower transportation costs, both financially and environmentally. Low weight also has a health aspect, in the sense that products are handled and carried by people during a long lifetime.

Fewer components:

The best solutions are often the simplest. By making a functional object with as few components as possible, you decrease the amount of tooling required, potentially lower the variety of resources needed, and decrease the amount of time needed to manufacture and assemble objects. This will help to keep weight low as well, but also reduce the number of materials needed to create tools, and energy expended during manufacture and assembly.

Right choice of materials:

Choosing the right materials is a decisive circular design principle. Using recycled materials such as post-consumer plastics and aluminium is truly circular. Not only will it help to reduce the amount of waste going to landfill, recycled materials also have a much lower carbon footprint than virgin raw materials due to less energy consumption during processing. Steering clear of harmful substances and toxic materials such as chromium and looking toward renewable materials are also key considerations.

Long lifespan:

Creating high-quality objects that are designed for long life can significantly reduce the use of resources, not only in materials but also in energy expended to replace the objects. A true circular product is designed to allow easy replacement of wearing parts, with spare parts available at low cost.

Designed for disassembly:

Once an object is at the end of life, designing for easy disassembly is crucial to enable deconstruction, sorting of base materials, and processing for recycling. If components are inseparably fused together (either by glues or non-accessible screws/fittings) then it can be very hard to separate and sort, and more likely to end up in landfill.